One stigma associated with letterpress printing: expensive.

We actually hear this a lot. And compared to other printing methods it can appear expensive. But… it doesn’t have to be. And the objective of this blog post is not to give you a bunch of long-winded information about the value of quality letterpress printing. You’re here. You already know the value. Instead, this post is about how you can make better decisions with your print project that will give you the most for your investment. So below are 5 tips towards cheap letterpress:

1. Keep it one-sided.

In all scenarios: Printing on only one side costs less. This is because your pressman only has to set up the press (clean, ink-up, register artwork, check Instagram) once to print your project. However, if you need the real estate of both sides, printing in the same color (see next tip) will be your best option for keeping the cost of your project down. This is because you eliminate a lot of the time consuming set-up that contributes to a higher overall cost. Setting up the press costs money.

Single color, single-sided business card for North of Wonderful.

2. Limit how many colors you need to print.

If you are familiar with letterpress printing, you know that only one color can be printed at a time (unless you run a split fountain). And after reading tip #1, you know that every time you print a color the press has to be set up (this also includes blind impressions). So in order to keep the cost of a project low, limit your colors. Limiting your colors limits how many times the press needs to be set-up. One way to save when printing on both sides is called work-and-turn, or work-and-tumble. This is where the front and back of a piece are printed at the same time with one plate, the press sheet is then flipped or rotated, and printed again on the opposite side. This is a great way to reduce set-up cost, but still print on both sides.

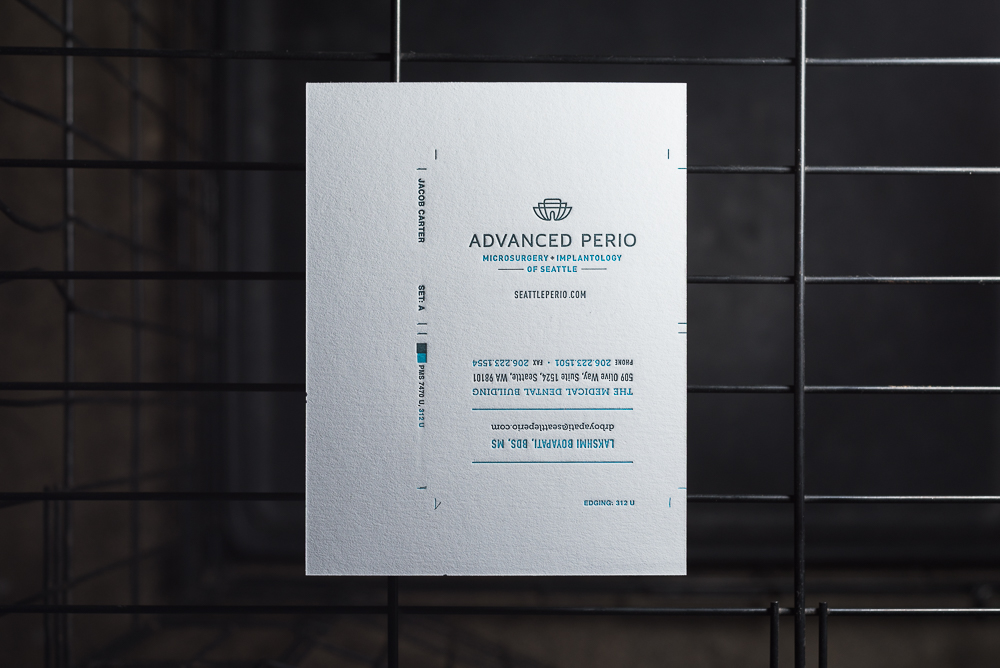

Example of work-and-turn/work-and-tumble style press sheet.

Split fountain business cards for The Color Run, edged to match.

I don’t even know how many colors this ended up being.

How many colors?

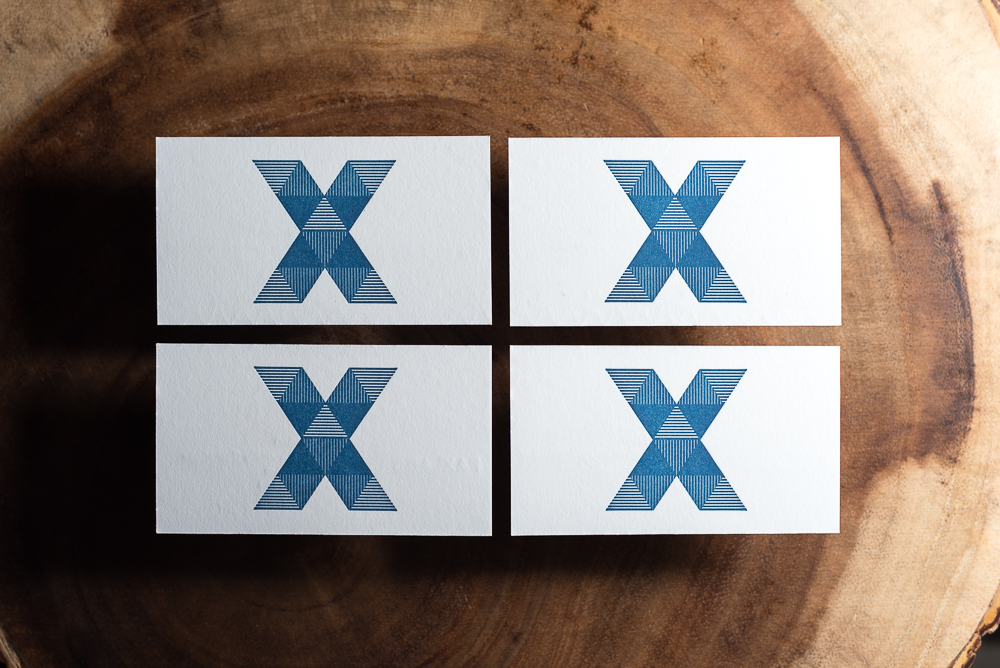

3. Use common elements.

When designing business cards for multiple people, design with printing in mind. Keep as many elements common, thus eliminating the need to set-up the press multiple times to accommodate small changes in each piece.

Logo, blind texture, and backs are common. This reduces set-up cost.

Common elements are common sense.

4. Print more.

I don’t need to elaborate much here. The more you print at one time, the lower the cost-per-piece will be. This is because you are spreading the cost of your set-up over more finished pieces, and the cost of additional materials are generally pretty insignificant in comparison.

Stacks on stacks on stacks.

5. Consider our online templates.

Why are our online templates so cheap? I really hate to spoil the mystery. But they are cheap because they incorporate all the above tips (one-sided, single color, black ink, high volume). And when you use a template from our store, you actually end up sharing a press-sheet with other clients, which in turn splits the set-up cost. These are one of our most popular products, and for good reason. We actually spent the last month shopping our competition, and our online templates remain to be the lowest cost letterpress business cards available domestically.

Cheers,

Matt