As with most professions.

Technical terms get thrown around a lot at the shop. So much so, that we tend to forget that it sounds like a foreign language to people that don’t work here. So in order to help decode some things we say, we have this here blog post explaining some letterpress terminology.

Plate:

When we say ‘Plate’, we are typically talking about a photopolymer plate. Just like the name implies, it is a light sensitive polymer that hardens when it is exposed to UV light. This is what is used in lieu of traditional metal or wood type in modern letterpress studios. We make our plates in house, which allows us to print anything we want with little lead time. This isn’t your grandpa’s typesetting.

Press sheet:

When your project is printing, it actually prints on a sheet that is larger than your finished piece. This is referred to as a press sheet. This gives the presses room to grab the sheet without damaging your project. Projects rarely get printed at their finished size.

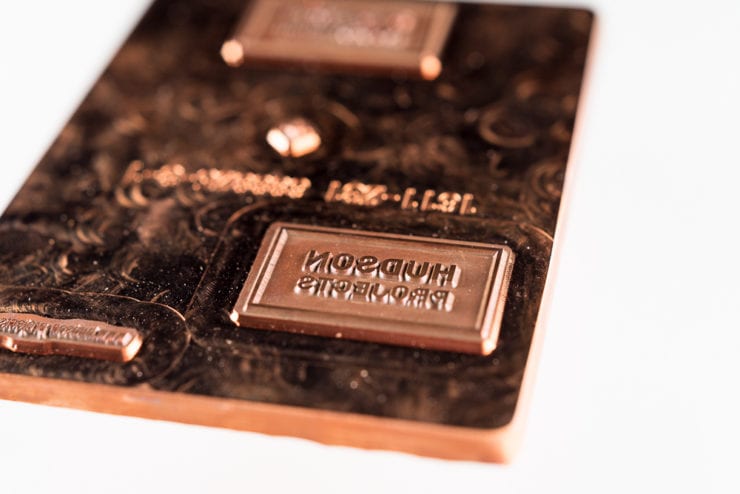

Registration:

This has nothing to do with summer camp. It’s the alignment of artwork on the press sheet. The above picture shows great registration of two colors on the same press sheet. If the registration were terribly unacceptable, it would look more like the below photo.

Finish Cut:

This is usually the last step before your project is complete. It is when a pressman trims your letterpress project from the press sheet size to the finished size. This process is done manually with a guillotine stack cutter unless it is a custom shape (the guillotine can only cut straight lines).

Die-Cut:

If your project isn’t finish cut on the guillotine, it’s probably going to be die-cut. Die-cutting is done on press, and is used to achieve consistent custom shapes. The dies are custom made from hardened steel blades inserted into wooden blocks. Die-cutting can also be used in other applications where finish cutting with the guillotine might not be the best option.

Impression:

The effect created by physically pushing the plate into the paper.

Set-up:

When the pressman cleans and lubricates the press. Registers the plate and loads the press with ink in the specified color for the project.

Flood:

A large printed area of the same color.

Knock-out:

The area within a flood that is not printed. The above picture is a great example of this.

Bleed:

Artwork that extends beyond the finished edge of a printed piece. You can see in the below photo that the flood extends past the finish cut crop marks.

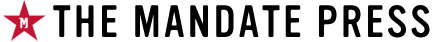

Foil Die:

A metal die that is heated and used to apply foil.

Pantone:

A color matching system that utilizes physical swatches to facilitate accurate color reproduction. Because the majority of our work is on uncoated paper, we use uncoated Pantone colors as references.

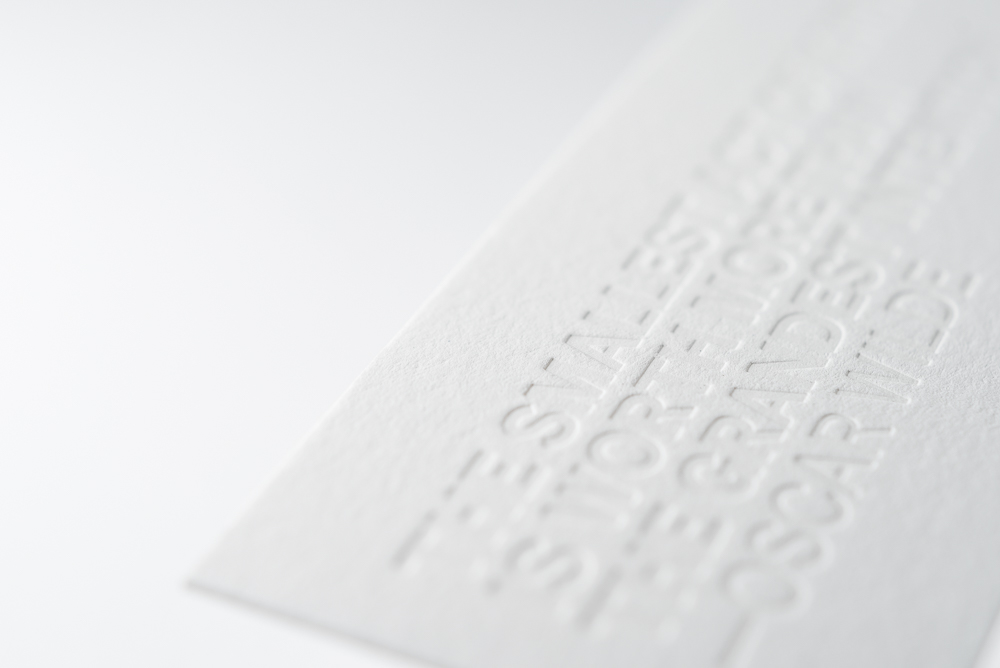

Blind:

An impression made with no ink.

Let us know if we missed anything. I’m sure we can think of some terms to add!

Cheers!

/Matt